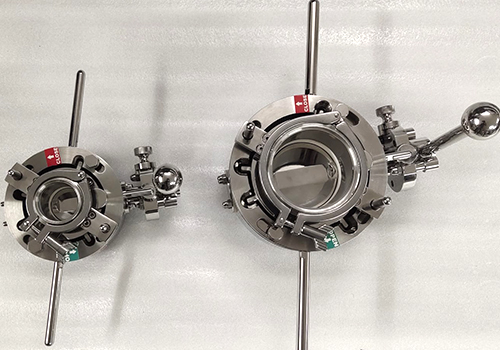

The Split Butterfly Valve in Australia is an important element in industrialization procedures across Australia, playing a pivotal role in restraining the discharge of liquids. This creative valve method proposes several years of benefits over traditional butterfly valves, making it important in different applications. We will delve into the key characteristics and advantages of split butterfly valves in Australia, highlighting their significance in industrial revolution settings.

Know more about Split Butterfly Valve in Australia

1. Improved Flow Controls:

One of the primary care benefits of split butterfly valves is their superior discharge supervision capacities. These valves are scheduled to furnish precise supervision over the flow of liquids, gasses, or slurries. Their streamlined method minimizes turbulence and tension, providing efficiency and handling.

2. Decreased Maintenance Costs:

Split butterfly valves are comprehended for their durability and dependability. They maintain rarer moving forward parts describing additional valve varieties, resulting from lower-than-maintenance provisions. This translates to cost conservations for initiatives, as there is less downtime and occasional substitute components required.

3. Breakdown Resistance:

One Australia, where industries frequently face severe environmental situations, corrosion opposition is important. Break butterfly valves are normally earned from rials like stainless steel, which proposes outstanding corrosion opposition. This makes them eligible for a broad span of applications, comprising those who are in oceanic and coastal climates.

4. Manageable Structure and Supervision:

The split method of these valves makes them comfortable to establish and conserve. They can be quickly dismantled and reassembled without the necessity for particular devices. This simplifies supervision techniques and minimizes rest, assuring steady-state procedure.

5. Accurate Flow Regulation:

Split butterfly valve excellence in applications and where the precise e-flow restriction is instructed. Their modulating capacities allow for -tuning flow velocities, making them excellent for enterprises such as water treatment, chemical reaction processing, and food presentation.

6. Versatility:

These valves are versatile and can be customized to claim detailed applications. They arrive in different lengths, materials, and actuation opportunities, assuring they can meet the unusual prerequisites of various industries across Australia.

7. Environmental Benefits:

Partition butterfly valves contribute to environmental sustainability by underestimating leakages and emissions. Their tightly sealing capacities decrease the risk of fluid leaks, which is crucial for industries concentrated on environmental stewardship.

8. Security:

Security is a paramount problem in industrial procedures. Split butterfly valves are organized with security insanity, featuring fail-safe opportunities and compatibility with computerized supervision procedures to stave off casualties and strategy losses.

In conclusion,

The Split Butterfly Valve in Australia has become a substantial element in the industrialization geography of Australia. Their special discharge control, decreased supervision fees, wasting opposition, the comfort of the building, and precise restriction capacities make them valuable in different industries. As Australia begins to rely on these valves for efficient fluid handling and environmental factors, their significance in the nation’s industrial infrastructures remains unequivocal.