Split Butterfly Valve

- Home

- Split Butterfly Valve

What is a Split Butterfly Valve ?

Stainless Steel Valve In Singapore

- Split Butterfly Valve (Say) or Containment Valve

- Provides a safe method of transferring product from one container or process vessel to another

- Transfer of Active Pharmaceutical Ingredients protection. Many different forms of ‘Containment’ are adopted within Pharmaceutical and Chemical manufacturing to create a barrier between the operator and the product being handled or processed.

How does SBV work ?

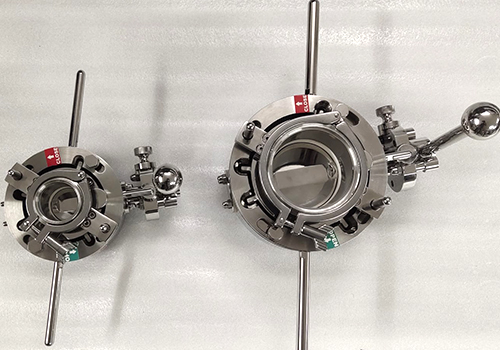

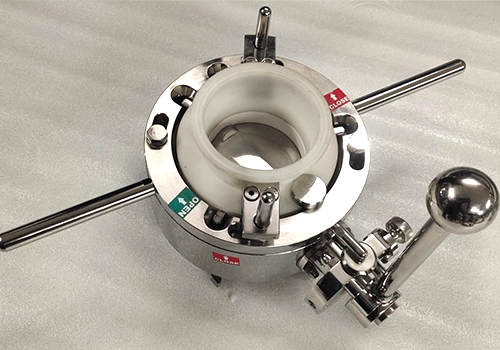

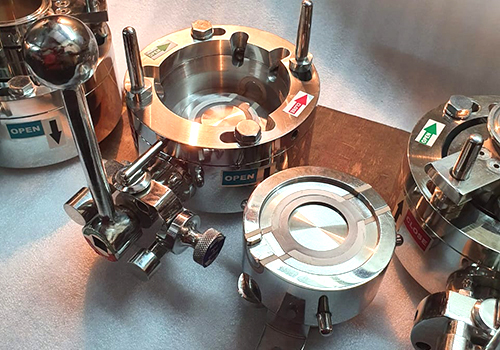

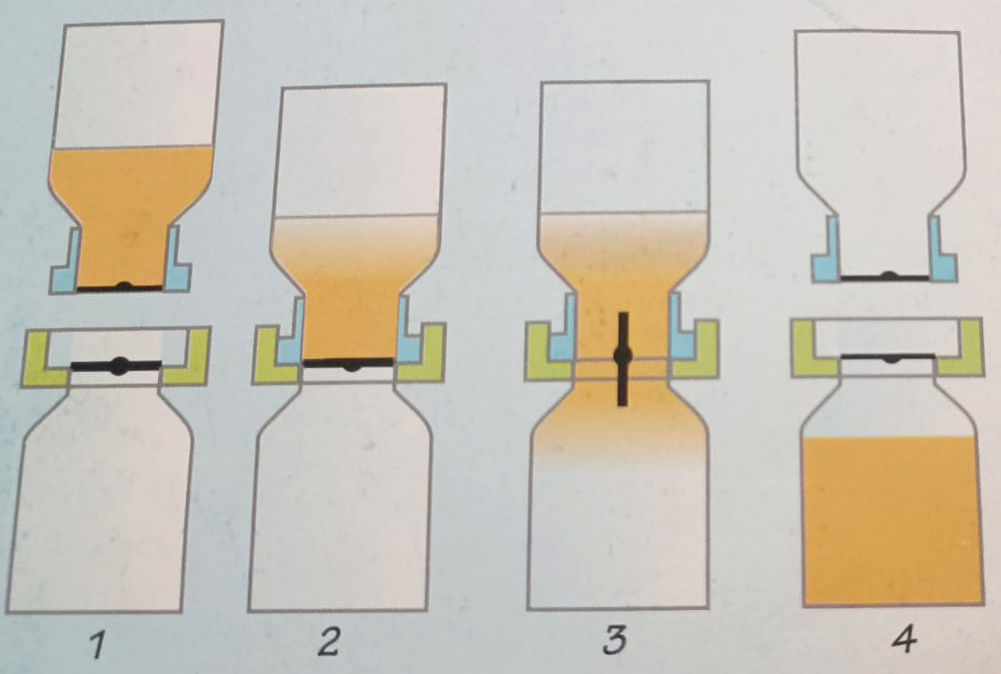

1. The Active and Passive units are docked together.

2. The two disc halves are locked in place to form a single sealed unit. The previously exposed Interfaces are now sealed together.

- The Active unit is the driving hag of the valve. Once operated (manual or automatic) the disc will open to allow the transfer of material through the valve. Once the transfer has taken place the valve is closed.

- The Active and Passive units are then unlocked and undocked ensuing a dust free transfer.

What are the benefits of using SBV technology ?

- Process your APIS, ensuring the safety of the operating environment by maintaining the required OEL (Occupational Exposure Limit).

- Protect your sensitive products and help eliminate cross contamination.

- Eliminate dust in the processing of raw materials reducing costs associated with cleaning and downtime.

- Increase flow and yield from product transfers.

What is Containment ?

- Containment is the formation of a barrier between the product/process and the personal operating environment during manufacturing process.

- Benefit containment solutions are utilised to protect the operator/environment from hazardous products during manufacturing processes.

- Secondary benefit the reality of containment equipment is the prevention of cross contamination, reduced need for cleaning and the creation of a more ergonomic and efficient working.

Measuring Containment ?

- The level of containment protection required is quantified as an OEL (Operator Exposure Level).

- Measuring the performance of equipment.

- Committee to provide a standard measure of containment effectiveness during solids processing in units of micrograms per cubic metre (µg/m3). Advantages provides by DAS valves.

Advantages provides by DAS valves

- Split valve technology ensure that your Powder handling processes are not only running effectively that you benefit from a low Cost

- An Independent supplier of containment valves

Design Features

- 1. Valves are designed to help you improve on the three key elements of overall Equipment Effectivenus (ODE)

- • AvailabilltY

- • Performance

- • Quality

Safety Interlocks

- A series of safety interlocks ensure that the Active and Panne units cannot be opened when they are not docked together. Also, the Passive unit cannot be accidently removed from the Active unit during powder transfer, but only once the valve is closed.

Benefits

- Ensure industry regulator

- Process toxic powders, ensuring the safety of your personnel and a dust free environment

- Reduce risk of cross contamination with closed transfers that limit manual intervention

- Meet product quality requirements

- Maximize yield transferring poorly flowing and high value product

Industrial Application

- Pharmaceutical & Biopharmaceutical

- Food & Beverage Materials

Powder

Granular

Tablets / Capsules

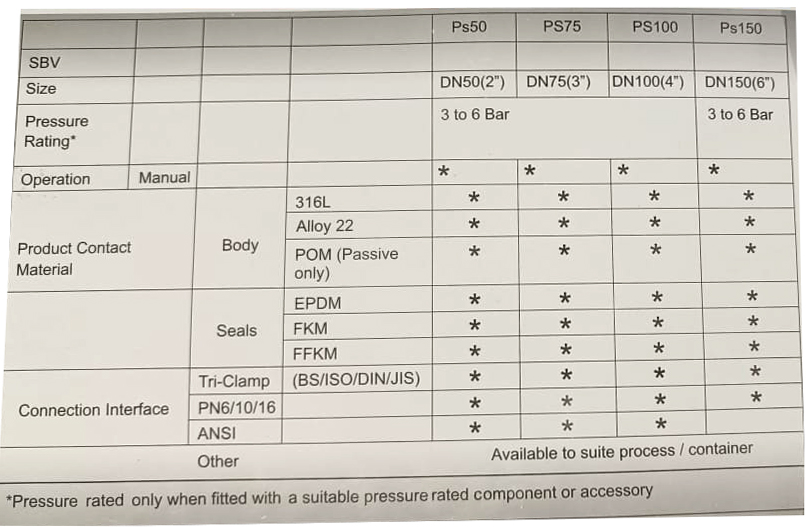

Specification