Rapid Transfer Port (RTP)

- Home

- Rapid Transfer Port

Divided Butterfly Valve In South Africa

Rapid Transfer Port (RTP) System

The Fast & More Safety Solution For All Transfer Operations

The transfer of material in & out of isolators requires specific technologies. This is also known as RTP or Alpha – Beta transfer ports. This transfer solution is now widely used for transfer of aseptic or toxic products in isolators.

The transfer system enable the user to introduce material into or to extract material from a closed barrier or to connect two devices with identical environments (e.g. isolators) without affecting their ambient characteristic. Our system is based on the interaction of two separate units – Alpha & Beta – each fitted with a door alock & a sealing function. The alpha units is mounted on a support (e.g. an isolator surface). While the beta unit is movable & seals off a container, a transfer isolator or any other suitable device.

Our system of transfer adapt them selves on walls of isolator wall of cleanroom : walls of BSI either still was of PSM our system is available in following range RTP 105, 190, 270, 350, 460. Our system offers you to select the type of container : chemically sterilisable or autoclavable.

RTP has Unique features ensuring safe operation

- Seal gasket or the highest containment

- Size available from 4" to 18" diameter

- 3-level interlock

- Door locked when no container present

- Door locked when container lidmissing

- Container locked when door opened.

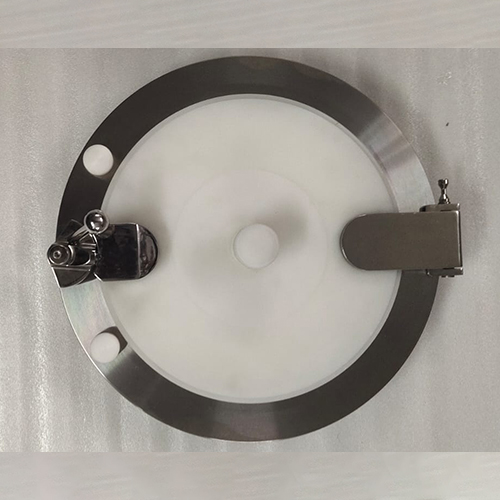

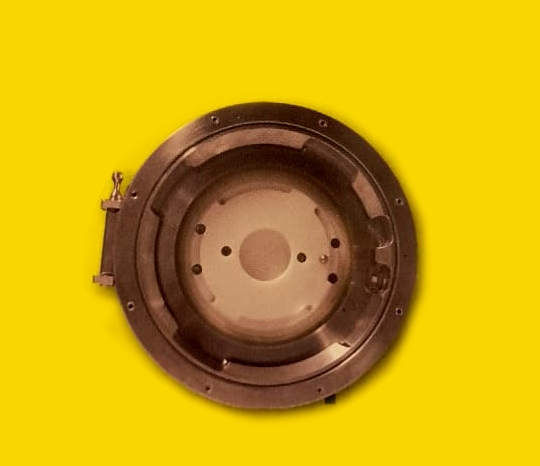

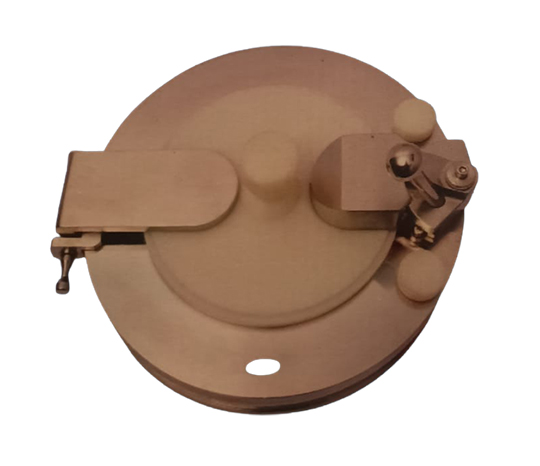

Beta Port

Specification system is recognised as being the safest method for introducing & removing sterile & toxic equipment without breaking containment. RIP containers confirm to the requirements for sterilization using as autoclave & are equipped with necessary accessories for ease of use.

Application : RTP mainly used for introducing equipment (pumpbody, stoppers. Capsules-) into an isolator after sterilization using an autoclave.

Key features

- 316L Stainless Steel Beta Flange & Door

- 316L Stainless Steel Body

Flexible Beta

- Body : The body is constructed from solid high quality stainless steel & beta door.

- Beta body : The beta flange is constructed from solid high quality stainless steel.

- Silicone seal : seal made of silicon is mounted into beta flange & HDPE Lid. It is ensure the tightness between beta door & beta flange. It ensure the tightness between alpha & beta doors. When the container is opened.